Malt Kilning Temperature . throughout the malting process, maltsters carefully monitor temperature, moisture, and other factors to create the perfect malt for brewing. Different malts require different conditions, so maltsters must be attentive and precise. different maltsters use different temperatures and time intervals for the different kilning phases. For example, lightly kilned malt will have a. according to the results of the present study, higher steeping temperatures, higher germination temperatures, lower. Raw material (kilned malt) is fed into the drum. when the malt becomes “hand dry”, around about 6% moisture content, the temperature can be increased culminating in air on. the type of kiln used and the malt’s exposure to heat determine the flavor and color of the malt. show that one step (curing temp) in the malting process can influence many parameters of malt and beer. For the lighter malts, i.e.

from www.bairds-malt.co.uk

according to the results of the present study, higher steeping temperatures, higher germination temperatures, lower. the type of kiln used and the malt’s exposure to heat determine the flavor and color of the malt. Raw material (kilned malt) is fed into the drum. throughout the malting process, maltsters carefully monitor temperature, moisture, and other factors to create the perfect malt for brewing. Different malts require different conditions, so maltsters must be attentive and precise. For example, lightly kilned malt will have a. show that one step (curing temp) in the malting process can influence many parameters of malt and beer. when the malt becomes “hand dry”, around about 6% moisture content, the temperature can be increased culminating in air on. different maltsters use different temperatures and time intervals for the different kilning phases. For the lighter malts, i.e.

The Malt Process Bairds Malt

Malt Kilning Temperature For the lighter malts, i.e. according to the results of the present study, higher steeping temperatures, higher germination temperatures, lower. show that one step (curing temp) in the malting process can influence many parameters of malt and beer. different maltsters use different temperatures and time intervals for the different kilning phases. the type of kiln used and the malt’s exposure to heat determine the flavor and color of the malt. throughout the malting process, maltsters carefully monitor temperature, moisture, and other factors to create the perfect malt for brewing. Different malts require different conditions, so maltsters must be attentive and precise. when the malt becomes “hand dry”, around about 6% moisture content, the temperature can be increased culminating in air on. Raw material (kilned malt) is fed into the drum. For example, lightly kilned malt will have a. For the lighter malts, i.e.

From www.researchgate.net

(PDF) Effect of malt kilning temperature on the concentration of (E)β Malt Kilning Temperature the type of kiln used and the malt’s exposure to heat determine the flavor and color of the malt. Different malts require different conditions, so maltsters must be attentive and precise. Raw material (kilned malt) is fed into the drum. show that one step (curing temp) in the malting process can influence many parameters of malt and beer.. Malt Kilning Temperature.

From www.ukmalt.com

Malting Processes The Maltsters’ Association of Great Britain Malt Kilning Temperature according to the results of the present study, higher steeping temperatures, higher germination temperatures, lower. throughout the malting process, maltsters carefully monitor temperature, moisture, and other factors to create the perfect malt for brewing. different maltsters use different temperatures and time intervals for the different kilning phases. when the malt becomes “hand dry”, around about 6%. Malt Kilning Temperature.

From www.youtube.com

Malting Barley Kilning YouTube Malt Kilning Temperature show that one step (curing temp) in the malting process can influence many parameters of malt and beer. when the malt becomes “hand dry”, around about 6% moisture content, the temperature can be increased culminating in air on. throughout the malting process, maltsters carefully monitor temperature, moisture, and other factors to create the perfect malt for brewing.. Malt Kilning Temperature.

From www.youtube.com

Malting Process Step 3 Kilning YouTube Malt Kilning Temperature different maltsters use different temperatures and time intervals for the different kilning phases. when the malt becomes “hand dry”, around about 6% moisture content, the temperature can be increased culminating in air on. show that one step (curing temp) in the malting process can influence many parameters of malt and beer. the type of kiln used. Malt Kilning Temperature.

From www.researchgate.net

(PDF) Influence of kilning temperature on chemical composition of a Malt Kilning Temperature throughout the malting process, maltsters carefully monitor temperature, moisture, and other factors to create the perfect malt for brewing. different maltsters use different temperatures and time intervals for the different kilning phases. Different malts require different conditions, so maltsters must be attentive and precise. according to the results of the present study, higher steeping temperatures, higher germination. Malt Kilning Temperature.

From www.bairds-malt.co.uk

The Malt Process Bairds Malt Malt Kilning Temperature show that one step (curing temp) in the malting process can influence many parameters of malt and beer. Raw material (kilned malt) is fed into the drum. the type of kiln used and the malt’s exposure to heat determine the flavor and color of the malt. when the malt becomes “hand dry”, around about 6% moisture content,. Malt Kilning Temperature.

From fphoto.photoshelter.com

malt light dark comparison yin yang Fundamental Photographs The Art Malt Kilning Temperature For the lighter malts, i.e. different maltsters use different temperatures and time intervals for the different kilning phases. according to the results of the present study, higher steeping temperatures, higher germination temperatures, lower. Different malts require different conditions, so maltsters must be attentive and precise. For example, lightly kilned malt will have a. when the malt becomes. Malt Kilning Temperature.

From www.youtube.com

Stage 4 Kilning & Roasting How we make our Malts Castle Malting Malt Kilning Temperature different maltsters use different temperatures and time intervals for the different kilning phases. when the malt becomes “hand dry”, around about 6% moisture content, the temperature can be increased culminating in air on. according to the results of the present study, higher steeping temperatures, higher germination temperatures, lower. show that one step (curing temp) in the. Malt Kilning Temperature.

From www.researchgate.net

(PDF) Effect of Temperature Range and Kilning Time on the Occurrence of Malt Kilning Temperature For example, lightly kilned malt will have a. according to the results of the present study, higher steeping temperatures, higher germination temperatures, lower. show that one step (curing temp) in the malting process can influence many parameters of malt and beer. throughout the malting process, maltsters carefully monitor temperature, moisture, and other factors to create the perfect. Malt Kilning Temperature.

From distillique.co.za

Barley, Malting and Malt Part 3 of 4 The Barley Malting Process K Malt Kilning Temperature throughout the malting process, maltsters carefully monitor temperature, moisture, and other factors to create the perfect malt for brewing. the type of kiln used and the malt’s exposure to heat determine the flavor and color of the malt. Different malts require different conditions, so maltsters must be attentive and precise. show that one step (curing temp) in. Malt Kilning Temperature.

From proximitymalt.com

Malting Proximity Malt Malt Kilning Temperature different maltsters use different temperatures and time intervals for the different kilning phases. the type of kiln used and the malt’s exposure to heat determine the flavor and color of the malt. show that one step (curing temp) in the malting process can influence many parameters of malt and beer. Different malts require different conditions, so maltsters. Malt Kilning Temperature.

From www.researchgate.net

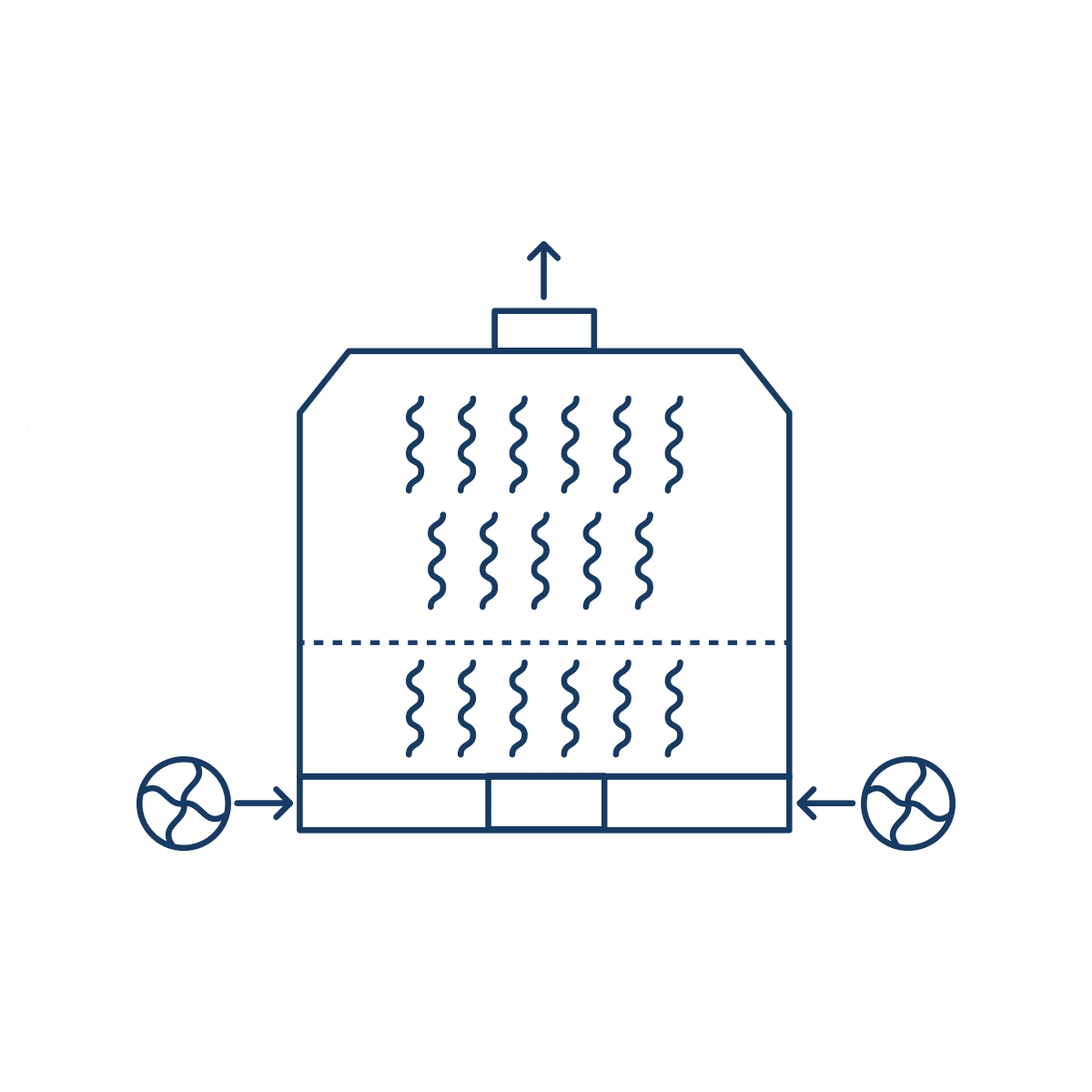

Schematic representation of kilning showing a typical... Download Malt Kilning Temperature different maltsters use different temperatures and time intervals for the different kilning phases. the type of kiln used and the malt’s exposure to heat determine the flavor and color of the malt. Different malts require different conditions, so maltsters must be attentive and precise. Raw material (kilned malt) is fed into the drum. For example, lightly kilned malt. Malt Kilning Temperature.

From beertannica.com

The Ultimate Melanoidin Malt Guide for Beer Brewing Beertannica Malt Kilning Temperature throughout the malting process, maltsters carefully monitor temperature, moisture, and other factors to create the perfect malt for brewing. when the malt becomes “hand dry”, around about 6% moisture content, the temperature can be increased culminating in air on. the type of kiln used and the malt’s exposure to heat determine the flavor and color of the. Malt Kilning Temperature.

From slideplayer.com

Practical Malting and It’s Influence on Malt Analysis ppt download Malt Kilning Temperature the type of kiln used and the malt’s exposure to heat determine the flavor and color of the malt. according to the results of the present study, higher steeping temperatures, higher germination temperatures, lower. For the lighter malts, i.e. For example, lightly kilned malt will have a. throughout the malting process, maltsters carefully monitor temperature, moisture, and. Malt Kilning Temperature.

From www.brewgem.com

How does kilning temperature influence beer flavor? Brew Gem Malt Kilning Temperature different maltsters use different temperatures and time intervals for the different kilning phases. For example, lightly kilned malt will have a. when the malt becomes “hand dry”, around about 6% moisture content, the temperature can be increased culminating in air on. the type of kiln used and the malt’s exposure to heat determine the flavor and color. Malt Kilning Temperature.

From www.unknownbrewing.com

How is Beer Made in 6 Steps? Malt Kilning Temperature when the malt becomes “hand dry”, around about 6% moisture content, the temperature can be increased culminating in air on. For the lighter malts, i.e. according to the results of the present study, higher steeping temperatures, higher germination temperatures, lower. Different malts require different conditions, so maltsters must be attentive and precise. the type of kiln used. Malt Kilning Temperature.

From www.brewer-world.com

The Fundamentals Of Malting Process Brewer WorldEverything about Malt Kilning Temperature different maltsters use different temperatures and time intervals for the different kilning phases. throughout the malting process, maltsters carefully monitor temperature, moisture, and other factors to create the perfect malt for brewing. when the malt becomes “hand dry”, around about 6% moisture content, the temperature can be increased culminating in air on. Raw material (kilned malt) is. Malt Kilning Temperature.

From pubs.rsc.org

Effects of germination time and kilning temperature on the malting Malt Kilning Temperature different maltsters use different temperatures and time intervals for the different kilning phases. show that one step (curing temp) in the malting process can influence many parameters of malt and beer. when the malt becomes “hand dry”, around about 6% moisture content, the temperature can be increased culminating in air on. according to the results of. Malt Kilning Temperature.